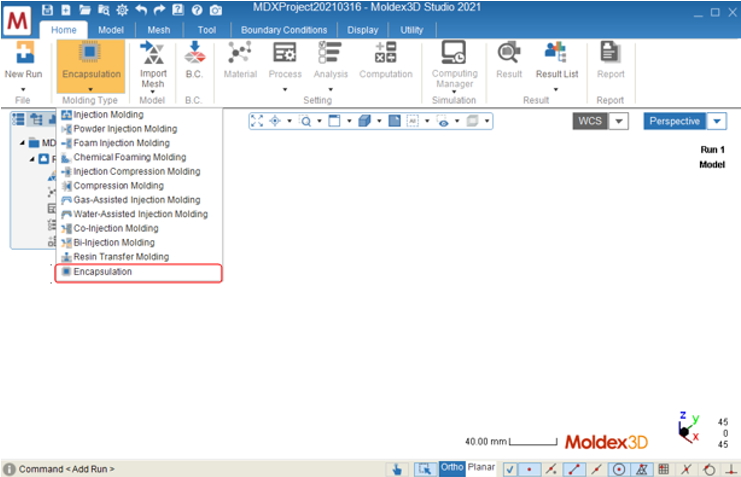

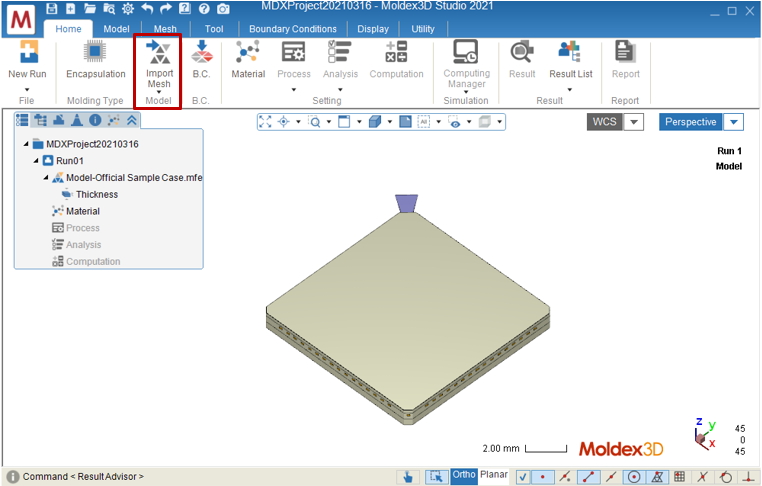

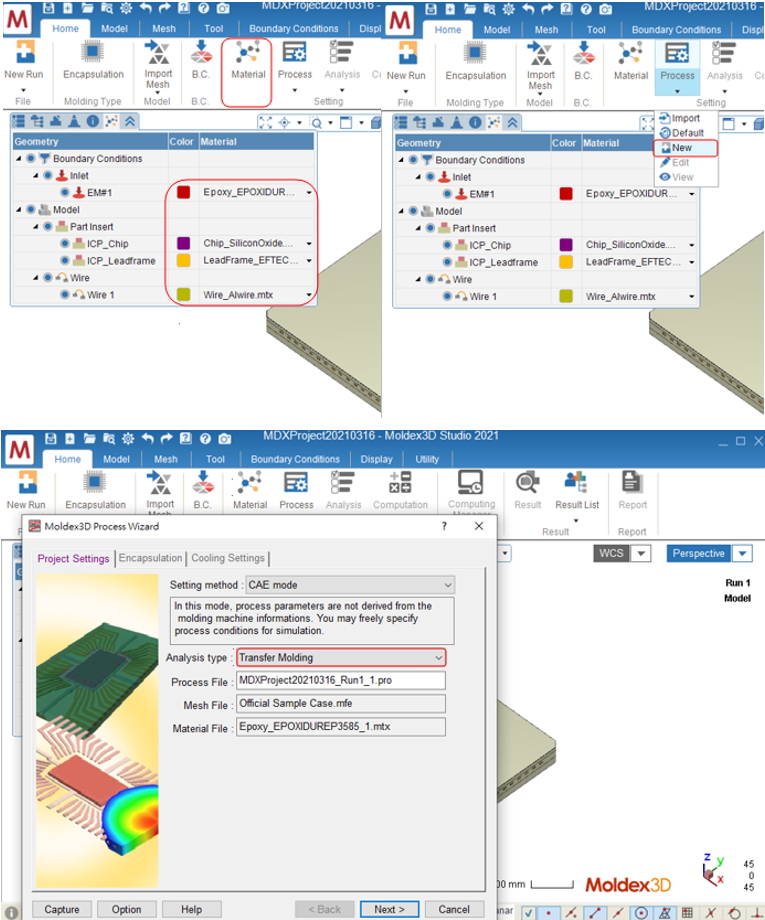

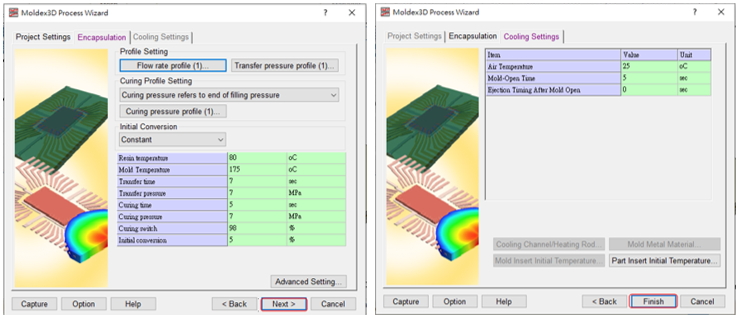

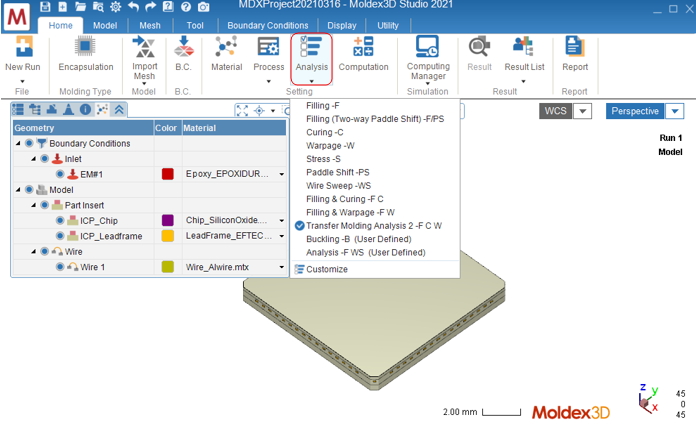

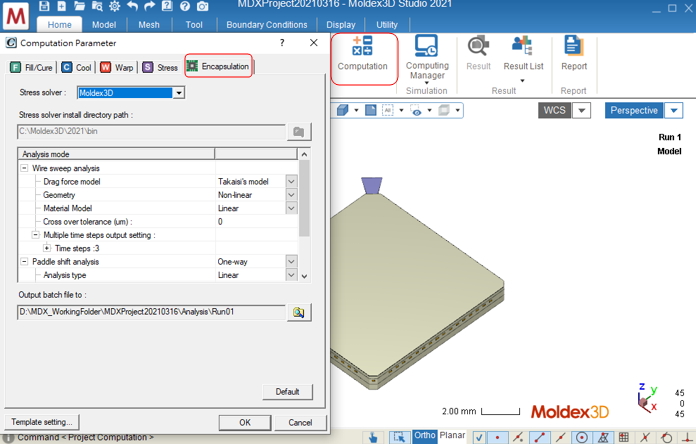

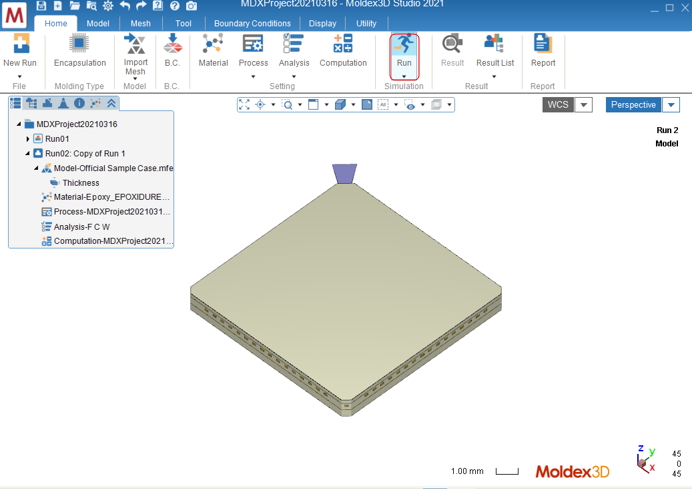

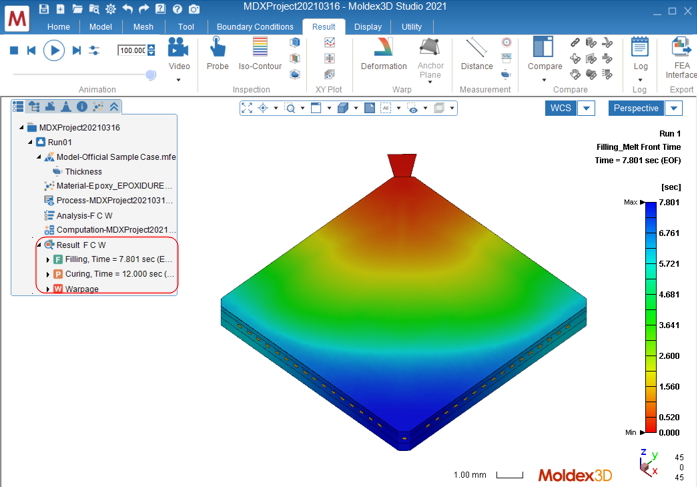

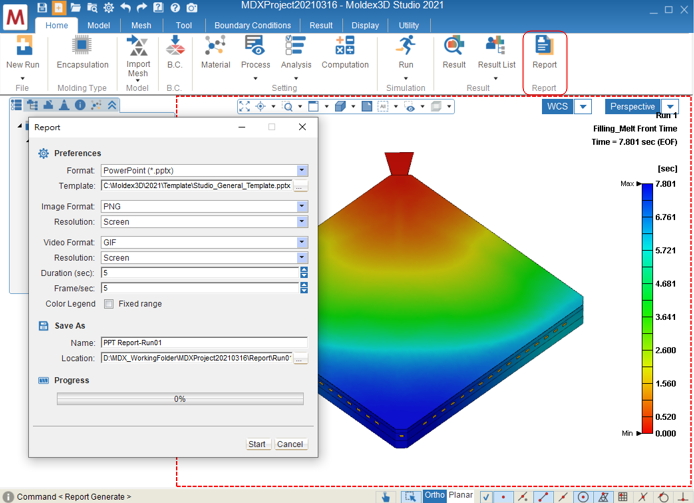

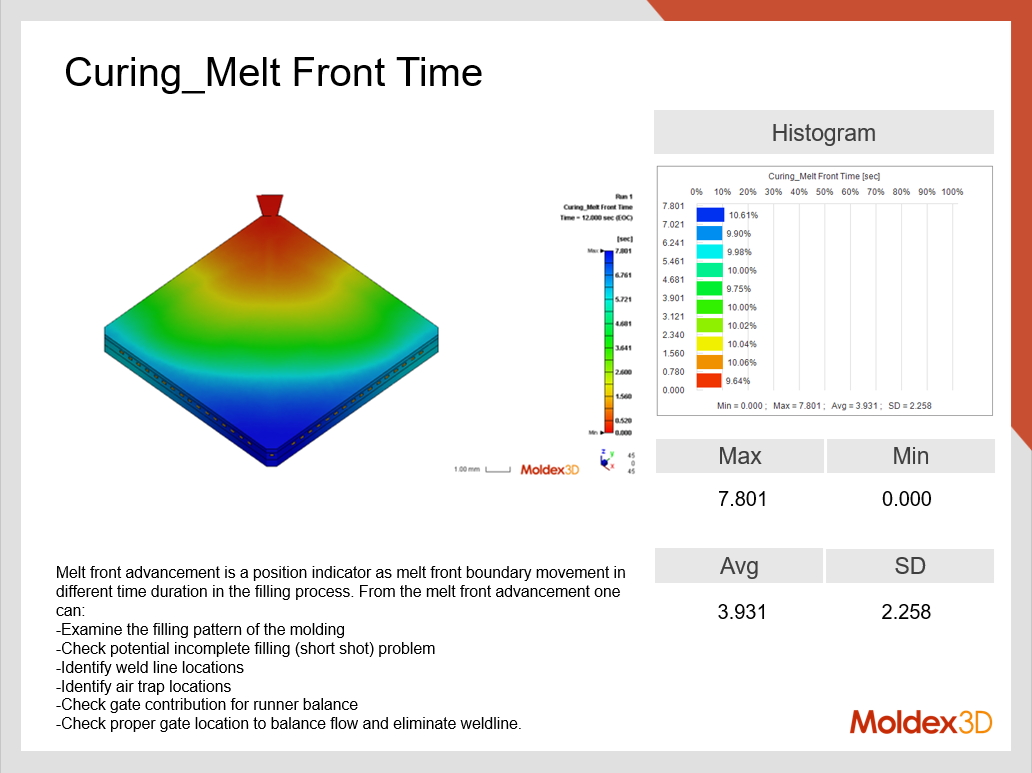

Plastic chip encapsulation is a molding process where chips are capsulated with epoxy molding compound (EMC) to prevent physical damage or corrosion. We should consider the interconnection between microchips and other electronics (i.e., wire bonding), curing phenomenon of thermoset material, and various control management of process conditions. Moldex3D Studio now supports IC transfer molding and helps mold designers to analyze the chip encapsulation process from filling, curing, to cooling. Significant molding problems can be predicted and solved upfront, helping engineers enhance chip quality and prevent potential defects more efficiently. The simulation results would also help in design optimization as well as cost reduction. Limitation Step 1: Model Preparation  Step 2: Material and Process Settings Define material for each component in the “Material Tree,†then click on “New†in the drop-down list in “Process†to enable Process Wizard for settings: (1) Choose “Transfer Molding†in “Analysis type.†(2) Finish setting up the process condition. Step 3: Analysis Settings For “Analysis Sequence,†select “Transfer Molding Analysis 2 – F C W.†(Users can also customize the analysis sequence by selecting “Customize.â€) Note: Projects can be submitted directly if no modifications are required, and users can also set up wire sweep analysis and paddle shift analysis in the “Encapsulation†tab. Step 4: Submit Projects After setting up the pre-processing, click on “Run†to start the analysis. Moldex3D will then call the Computing Manager for users to check the calculation progress and details. Note: Users can also click on “Computing Manager†to launch Computing Manager and adjust settings for parallel and remote computing before submitting projects. Step 5: Results Checking and Report Exportation Results will be shown in “Result†in the project tree when the analysis is done. Click on “Result†to switch from “Homeâ€Â to “Resultâ€Â tab. In “Result†tab, users can use different post-processing tools to view customized or advanced results. Users can use the “Report Wizard†in the Studio to automatically generate reports. Click on “Reportâ€Â in “Homeâ€Â tab to open the “Report Wizard.†Set the content format before exporting the report. In the “Preference†section, users can customize the format, image, and video in each report. Key in the report name and location and click on “Startâ€Â to start to generate the report. BMC Communication Devices Mould

BMC communication equipment mold

customization: manufacturing with superb technology and excellence.

Mold Design

In the customization process of BMC

communication equipment molds, mold design is the first step. Our technical

team relies on rich experience and professional technical knowledge to design

mold solutions that not only meet product functional requirements but also

adapt to the production process according to the customer's specific

requirements and usage environment. Through accurate calculation and simulation

analysis, the rationality, stability and reliability of the mold structure are

ensured, laying a solid foundation for subsequent production.

Precision Plastic Molds Manufacturing

We use advanced manufacturing equipment and

processes to ensure the accuracy and quality of mold making. From the selection

of raw materials to the control of the processing process, we strictly follow

industry standards and quality requirements. Through high-precision CNC

machining, EDM machining and polishing processes, the dimensional accuracy,

surface finish and fit accuracy of the mold are ensured, thereby improving the

molding quality and production efficiency of BMC communication equipment.

Optimize Production Process

In addition to mold design and mold making,

we are also committed to optimizing production processes and improving

production efficiency. Through in-depth research and analysis of the production

process, we find the key factors affecting production efficiency and product

quality, and take effective measures to improve them. For example, optimizing

the injection molding process parameters, improving the cooling efficiency of

the mold, etc., thereby shortening the production cycle, reducing production

costs, and improving the market competitiveness of the product.

Personalized Customization

We understand that each customer's needs

are unique, so we provide a personalized, customized service. Whether it is the

size, shape or special requirements of the mold, we can customize it according

to the needs of our customers. Our technical team will communicate closely with

customers to understand their specific needs and provide professional

suggestions and solutions to ensure that the final product can meet customer

expectations and requirements.

Quality Assurance and After-Sales Service

We know that quality is the lifeline of an

enterprise, so we strictly control the quality of molds. Each mold will undergo

strict quality inspection and testing before leaving the factory to ensure its

stable performance, safety and reliability. In addition, we also provide

comprehensive after-sales service to ensure that customers can get timely

solutions when they encounter problems during use. Our professional team will

provide customers with technical support and solutions to help customers better

use and maintain molds.

BMC satellite navigation mold,BMC mobile case mould,BMC Compression Electric Meter Box Mould Dongguan Hongke Plastic Precision Mould Co.,Limited , https://www.scientificmolds.com

Jasmine Ho, Engineer at Technical Support Team, Moldex3D

Operating Procedures

November 30, 2024