I will be honest, I knew very little about ship to shore cranes (STS) and even less about the various other options that were available to our customers. So, I did some digging to see what we are up against. Firstly, ports can be chaos! But a controlled chaos! There are multiple people and machines working together in unison to increase the velocity of each port. Cranes are getting bigger, faster and more advanced and they need technology to be comparable in order to keep control of the chaos. Our energy chains and flexible cables are in use in over 10,000 port installations around the world and have proven their worth in real, harsh environments. The fields of application include ship-to-shore cranes, bulk cargo handling cranes, RTGs, RMGs, Goliath cranes, spreaders, reach stackers, etc. The key thing that makes igus® energy chain systems so popular in the crane industry is the low maintenance element. These are a direct alternative to festoon cable management systems or cable drums for port cranes, increasing reliability and minimising unplanned stoppages. Once the system is installed, the customer has complete confidence that the system will fair against all weather conditions, giving the customer complete peace of mind. This is worth its weight in gold. The e-chain® systems protect the cables, are stabilised, structured and offer complete dependability. igus® can give guidance and support when there is a unique design challenge, in fact we relish the challenge! If you still needed convincing that igus® e-chains® are the way forward here are some more interesting facts…. The e-chain® offers a space saving design. It uses approx. 50% less cable than a festoon system. With igus® energy chains you can run all services within the same system such as power, data, control, fibre optic, and even fluids or gasses, plus you can easily add services if required with no additional parts needed. Our cables are not only securely protected in our e-chains® but are installed within troughs, giving additional protection and structure to the system. Festoon cables are not controlled or structured and are subject to getting caught in the elements. With the cranes so high up, there can be large temperature fluctuations, severe vibration or movements of the entire steel construction.  If the cables got damaged, which could easily happen with a festoon system, this could result in downtime whilst replacements or repair work is carried out. igus® can deliver a complete system including, chainflex® cables, connectors and trough giving you the one stop shop. This is quick and easy to install; the tailor-made solution includes igus® fully installing the system for you! In order to be able to offer a precise system, we use an integrated linear system. This in layman’s terms, means we have a floating element to the system, allowing for any misalignment to be maintained within the tolerance of the trough. In Cologne, our headquarters boosts a 3800m2 test lab with 65 test machines. 250 tests are conducted simultaneously and 10 billion e-chain cycles per year are tested! We also offer a 4 year guarantee on both our e-chains® and chainflex® cables. This proves that we are confident in the quality of our products. Cranes are an essential and integral part of keeping economies running. They are massively overlooked but without them, how would one get freight off ships onto shore? Literally ship to shore! We can all do our bit in ensuring that the cranes are kept in sound working order and igus® e-chain® systems are the way forward, to protect the reliability of unloading essential goods safely and securely. For more blogs relating to igus® energy chains, click here. Chongqing Wishcarry Trade Co.,Ltd. , https://www.wishcarry-cooler.com

igus® can help control that chaos, here is how:

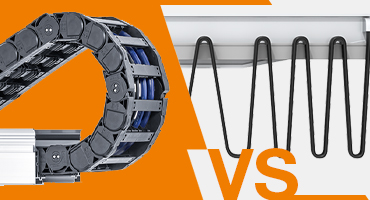

Key points about igus® e-chains® and how we compare to festoon systems

Shorter cable lengths

All services within one system

Security

Tailor-made solutions

Perfect alignment

Testing, testing, testing

Verdict

hbspt.cta.load(3055426, '4c98875b-ee2e-441e-9248-b524ea3f3146', {});

hbspt.cta.load(3055426, '4c98875b-ee2e-441e-9248-b524ea3f3146', {});

November 20, 2024