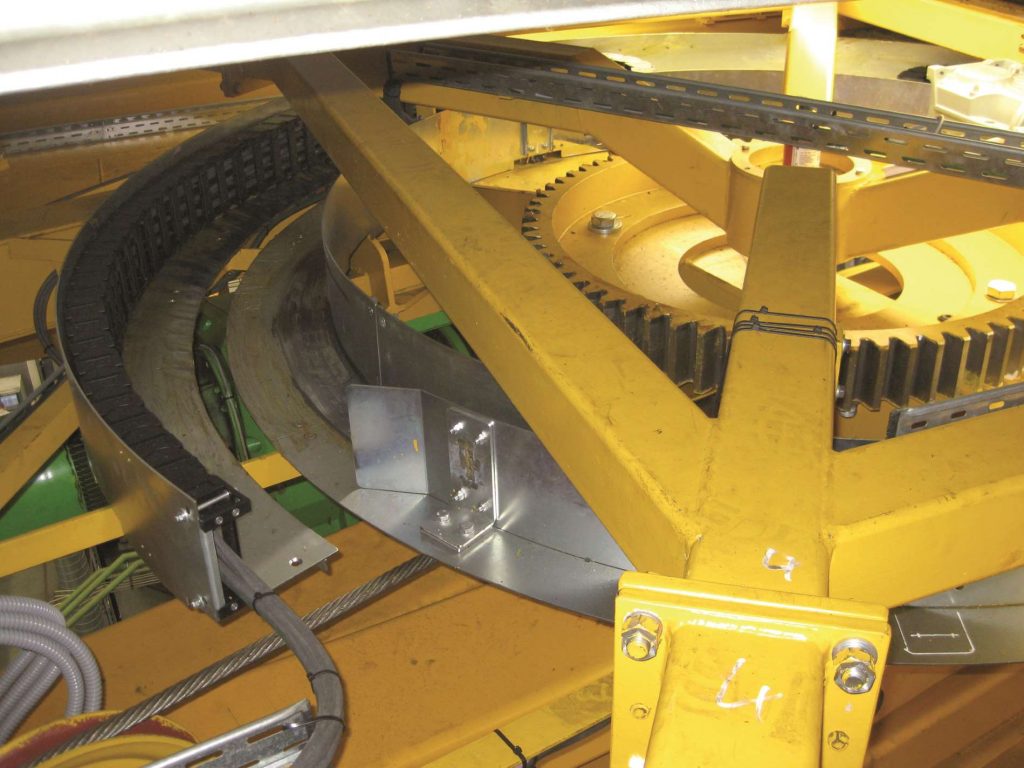

Compact cable requirements can sometimes be a challenge.  If the customer has a tight installation space, this can limit the choice of possible solutions. A prime example of an industry where such challenges arise is designing an indoor crane system. Luckily, igus® have developed a couple of perfect solutions for such challenges…. By adding a slewing gear on to the trolley, this enables a rotation of the load beneath the crane girder. With the classic festoon system, the cable loops are usually hung on the outside of the slewing gear. The cables are guided with cable trolleys along a curved I-beam. The size of the angle of rotation determines the number of cable loops required. A low installation height can be problematic due to the restricted space with a festoon system. Replacing the festoon system with a secure modular igus® alternative means the cables are protected and this avoids downtime. The classic e-chain® systems igus® supplies still offer a space-saving alternative to some of the other methods. Installed around the hoist, the chain system requires a remarkably small amount of space. A round guide trough helps to guide the side mounted chain. This allows rotation angles of up to 540° and rotation speeds of up to 360°/s. Larger cables can also be guided through these energy chains,  requiring very little space. This can be achieved by dividing the cables and installing two opposed running chains in the same rotary guide trough. However, such a rotary movement creates specific demands on the cables used inside the chain. The cables are bent very tightly along the bending radius of the chain which can cause issues.  It is highly recommended to use suitable cables within the e-chains®, such as our chainflex® products. This ensures a long service life and will minimise equipment downtime. Different applications and conditions on site require an individual design of the guide trough. Taking this into consideration, igus® has put together a modular system with different guide channels that can be used. The igus® website highlights the top 10 tips for a long-lasting rotary energy supply to help identify the right trough design for each application. igus® wants to help ensure that the life of the chain outperforms expectations. Producing chains in low maintenance, lubrication-free iglidur® materials enables igus® to be able to offer guaranteed lifetimes, ensure minimal downtime and with the configurator tool, allow the customer to configure their own design based on their requirements. In addition to constraints such as having a low installation height, there are also other aspects that need to be considered for the use of a chain system. The maintenance effort and the associated maintenance costs of individual cable routing systems are often underestimated. Some traditional systems require regular lubrication, something which igus® has eliminated with its lubrication-free materials. In order to maintain a festoon system, the complete crane must be taken out of service. In comparison, the energy chain system is almost maintenance-free and therefore downtime should be limited as there are no components installed on the igus® e-chain® that require lubrication. The design stage of any e-chain® and cable combination can be manufactured according to the customer requirements and any specific conditions required on site. This can involve an individually adapted energy chain system and cable configuration. With the online CAD configurator tool, individual 3D models of the required trough system, including the chain, can be quickly generated and integrated into the crane design. We keep a range of standard MRM, multi rotation modules, on the shelf at igus®. Bespoke designs can be manufactured to customer requirements.  For more information please visit the igus® website. Alternatively, please contact the Crane Specialist Dan Seeney: Motor And Other Series,Single Phase Ac Motor,AC Single Phase Motor,Magnetic Levitation Motor Hunan Nongle Machinery Co., Ltd. , https://www.nongleagro.com

Slewing trolley system:

Festoon system:

Classic energy chain systems:

Guide trough design:

Maintenance:

3D configurator:

November 23, 2024